| Product

Name: GWC Medium Frequency Copper Melting Induction Furnace |

Hits: 18151 |

|

|

| Payment Terms: |

30% in advance, balance by T/T or L/C at sight |

| Minimum Order: |

1 Piece |

| Package: |

plywood box and Nude |

| Brand Name: |

ELE |

| Capacity |

10kg~10,000kg |

| Shell Material |

steel or aluminum |

| Tilting Type |

hydraulic or mechanical | |

|

|

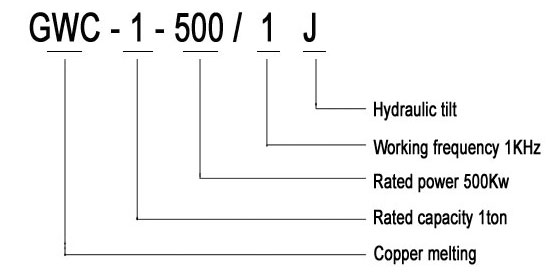

This GWC Series Coreless Medium Frequency Induction Smelting Furnace, also called as Induction Melting Furnace or Induction Oven is for melting copper, brass and its alloy. |

|

|

|

1. Solid steel structure and durable;

2. Good magnetic isolation, safe and reliable;

3. Solid frequency conversion power supply, easy operation; Adjustable power rate, easy operation and maintenance;

4. Easy to start up with load or free of load. |

|

|

Electrical Feature:

1. Digital CMOS chip (U. S. ASIC-2-12), with the highest degree of integration at home, is used in control circuit, the overall machine controlled through one single panel;

2. Frequency-sweep zero voltage start, high success rate, no shock;

3. Automatic resistance adjustment, permanent power output, 10-20% energy saved in comparison with domestic traditional machine of the type;

4. Auto phase sequence adaptation, free of synchronization;

5. Good performance in reload staring, auto recovery;

6. Highly integrated in controlling circuit, free of use of high-rate starter and relay loop, fairly low failure rate;

7. Wholly digital design, strong in anti-interference, no temperature shift when in continuous working;

8. Multi-protection functions (for over current, over voltage, insufficient water pressure, power failure, or phase absence), and mishandling will not cause damage to machine. |

|

|

|

Model |

Rated Capacity |

Rated Power |

Input Volt. (6pulse) |

DC Volt. |

Melting Rate |

Working Freq. |

Rated Temp. |

|

T |

Kw |

V |

V |

T/H |

Hz |

oC |

|

GWC-0.5-250/1J |

0.5 |

250 |

380 |

500 |

0.65 |

1000 |

1250 |

|

GWC-0.75-400/1J |

0.75 |

400 |

380 |

500 |

0.9 |

1000 |

1250 |

|

GWC-1-500/1J |

1 |

500 |

380 |

500 |

1.2 |

1000 |

1250 |

|

GWC-1.5-800/0.5J |

1.5 |

800 |

690 |

880 |

1.8 |

500 |

1250 |

|

GWC-2-1000/0.5J |

2 |

1000 |

690 |

880 |

2.2 |

500 |

1250 |

|

GWC-3-1500/0.5J |

3 |

1500 |

690 |

880 |

3.1 |

500 |

1250 | |

|

|

1. Furnace body

2. Hydraulic tilting device,

3. Operation table

4. Medium frequency power supply

5. Low voltage power cabinet

6. Capacitor bank

7. Water cooling cable

8. Crucible Mould

9. Water tanks

10. Water temperature and pressure annunciator

11. Furnace leakage alarm |

|

|

|

|